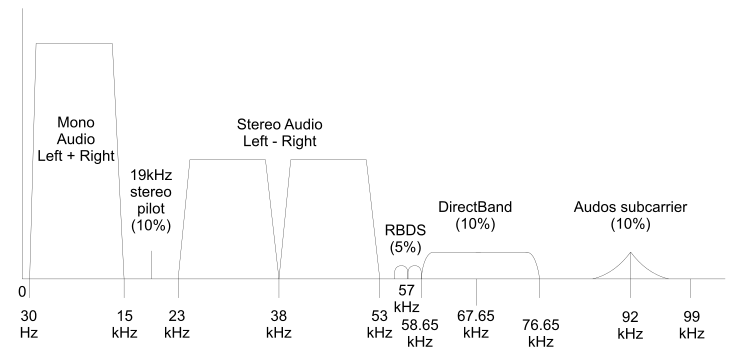

A mono FM receiver – with zero support for stereo whatsoever – should indeed exhibit greater sensitivity and selectivity when tuning stations, because they need only electronically filter for a ~15 kHz mono signal within the assigned 200 kHz band for each distinct station.

A wider filter suitable for stereo reception could have similar behavior, but it would require better/pricier components or a greatly modified design for the radio. In most cases, sensitivity is sacrificed to keep the price point of a stereo receiver, since people care more about properly selecting nearby radio stations rather than faraway stations. Even when a stereo receiver were – somehow – receiving a mono broadcast, the penalty is already paid because of the receiver’s design.

Source: Wikipedia

IMO, motorcycle haulers are readily available, handle weights well in excess of typical ebikes, can accommodate fattires as needed, and have the only drawback of requiring the bike to be secured using tow straps or chain. Though depending on the weight of an ebike, this may very well be preferable.